Language

| Availability: | |

|---|---|

| Quantity: | |

Production Description:

LENO Stainless Steel No shear transfering Sine pump

Special two sine curve like vane is taken,instead of rotor,epicyclic gear or piston,and it runs with a movable panel and a fixed line,forming a special volume pump and realizing liquid super low shear,without pulse feeding,even in condition of 10bars back pressure(water feeding),there won't be any movement on pressure gauge.

An exquisite product or a good functional product will have a simple configuration with few components. The sine pump is no exception.

The sine wave shape of the impeller means that cavities can be formed at every rotation (four cavities can be formed every time the lining space is passed). A control panel divides the pump cavity into suction and extraction chambers to ensure pressure tolerances at exit and entrance. In addition, the control panel also lubricates the pump bearing by product in compulsion.

High viscosity, excellent efficiency, and the best choice for super low shear feedings is the sine pump

With a lot of solid particles and fragile product, super low shear feeding can be achieved without damage. High viscosity performance can reach 4,000,000 cps.Feeding is stable with no pulse.

1. What is a Stainless Steel Sine Pump?

A stainless steel sine pump is a positive displacement pump that utilizes a sine wave principle to achieve continuous fluid transfer through sinusoidal motion of the rotor. Key components (such as the rotor and pump casing) are made of 304/316L stainless steel, offering corrosion resistance, high precision, and low pulsation. It is ideal for industries with strict hygiene requirements, including food, pharmaceuticals, and chemicals.

2.Structural Features

Sine Wave Rotor Design: Minimizes shear stress, suitable for sensitive fluids.

Hygienic Sealing: Supports CIP/SIP (Clean-in-Place/Sterilize-in-Place) and complies with FDA standards.

Modular Design: Facilitates maintenance and replacement of wear parts.

3.How to Install and Maintain It Correctly?

Installation Requirements:

Ensure the pump is mounted horizontally to avoid vibration.

Install a filter (≥50 mesh) at the inlet pipeline.

Maintenance Tips:

Regularly inspect rotor wear (recommended every 6 months).

Use only OEM replacement parts for seal changes.

4.Common Issues and Solutions

Unstable Flow: Check for low inlet pressure or pipeline blockages.

Abnormal Noise: May indicate bearing wear or rotor imbalance; require immediate inspection.

Leakage: Inspect for seal aging or improper installation.

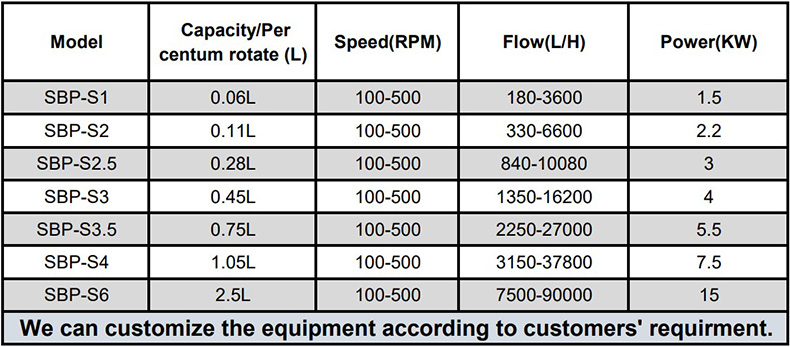

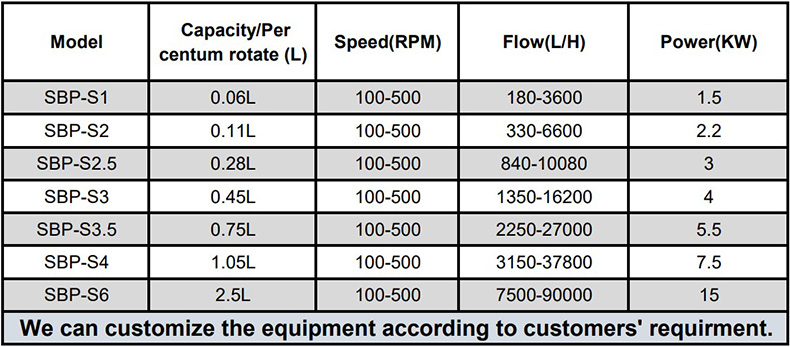

5.How to Choose the Right Stainless Steel Sine Pump?

Based on Media Properties: Corrosiveness, viscosity, and particle content.

Based on Process Requirements:Flow accuracy, pressure range, and hygiene level.

For more detailed technical specifications or operation videos, please refer to.

Production Description:

LENO Stainless Steel No shear transfering Sine pump

Special two sine curve like vane is taken,instead of rotor,epicyclic gear or piston,and it runs with a movable panel and a fixed line,forming a special volume pump and realizing liquid super low shear,without pulse feeding,even in condition of 10bars back pressure(water feeding),there won't be any movement on pressure gauge.

An exquisite product or a good functional product will have a simple configuration with few components. The sine pump is no exception.

The sine wave shape of the impeller means that cavities can be formed at every rotation (four cavities can be formed every time the lining space is passed). A control panel divides the pump cavity into suction and extraction chambers to ensure pressure tolerances at exit and entrance. In addition, the control panel also lubricates the pump bearing by product in compulsion.

High viscosity, excellent efficiency, and the best choice for super low shear feedings is the sine pump

With a lot of solid particles and fragile product, super low shear feeding can be achieved without damage. High viscosity performance can reach 4,000,000 cps.Feeding is stable with no pulse.

1. What is a Stainless Steel Sine Pump?

A stainless steel sine pump is a positive displacement pump that utilizes a sine wave principle to achieve continuous fluid transfer through sinusoidal motion of the rotor. Key components (such as the rotor and pump casing) are made of 304/316L stainless steel, offering corrosion resistance, high precision, and low pulsation. It is ideal for industries with strict hygiene requirements, including food, pharmaceuticals, and chemicals.

2.Structural Features

Sine Wave Rotor Design: Minimizes shear stress, suitable for sensitive fluids.

Hygienic Sealing: Supports CIP/SIP (Clean-in-Place/Sterilize-in-Place) and complies with FDA standards.

Modular Design: Facilitates maintenance and replacement of wear parts.

3.How to Install and Maintain It Correctly?

Installation Requirements:

Ensure the pump is mounted horizontally to avoid vibration.

Install a filter (≥50 mesh) at the inlet pipeline.

Maintenance Tips:

Regularly inspect rotor wear (recommended every 6 months).

Use only OEM replacement parts for seal changes.

4.Common Issues and Solutions

Unstable Flow: Check for low inlet pressure or pipeline blockages.

Abnormal Noise: May indicate bearing wear or rotor imbalance; require immediate inspection.

Leakage: Inspect for seal aging or improper installation.

5.How to Choose the Right Stainless Steel Sine Pump?

Based on Media Properties: Corrosiveness, viscosity, and particle content.

Based on Process Requirements:Flow accuracy, pressure range, and hygiene level.

For more detailed technical specifications or operation videos, please refer to.