Language

Designed for production teams who need repeatable emulsification and dispersion in 100–1000 liter tanks and drums.

Helps reduce lumps, fisheyes, separation, and rework, so batches move faster from mixing to QC release.

Hydraulic lifting improves positioning control on large vessels, making operation safer, cleaner, and more consistent across shifts.

Built around a rotor–stator high shear principle that targets the real problem: insufficient shear at the moment ingredients first meet.

Available in SS304 / SS316L, with additional options such as coatings and 2205 for demanding media.

Supported by engineering selection guidance and one-year quality assurance.

| Availability: | |

|---|---|

| Quantity: | |

In many factories, the word “mixing” hides the true cost: the hours spent fixing what didn’t disperse correctly. A shampoo can look perfect in the tank but reveal tiny specks under inspection lights. A cream can feel smooth at first touch, then show graininess after a day. A sauce can pass viscosity today and separate during transport tomorrow. These issues are rarely solved by “mix longer.” They’re solved by applying the right shear, in the right place, at the right time.

This hydraulic lifting high shear mixer is built for that critical moment. A rotor spins at high speed near a fixed stator, and the product is pulled through a narrow gap. In that tight zone, the material experiences strong shear, intense turbulence, and localized high velocity—conditions that help break down agglomerates, improve wet-out, and create finer, more stable emulsions. You can often sense the change during production: the surface becomes more uniform, the batch “pull” feels steadier, and the product’s appearance becomes cleaner as dispersion finishes sooner.

Because it’s designed for large vessels (100–1000 L), the hydraulic lifting structure matters as much as the shear head. Positioning a high shear head too shallow can draw air; too deep can reduce circulation efficiency. Hydraulic lifting helps turn “operator intuition” into a repeatable procedure—position, run, lift, clean—so quality is less dependent on who is on shift and more dependent on controlled process steps.

Rotor–stator high shear head for faster emulsification and dispersion, especially where ordinary agitators only move bulk fluid.

Hydraulic lifting system for controlled vertical positioning on large tanks and drums, improving repeatability and safety.

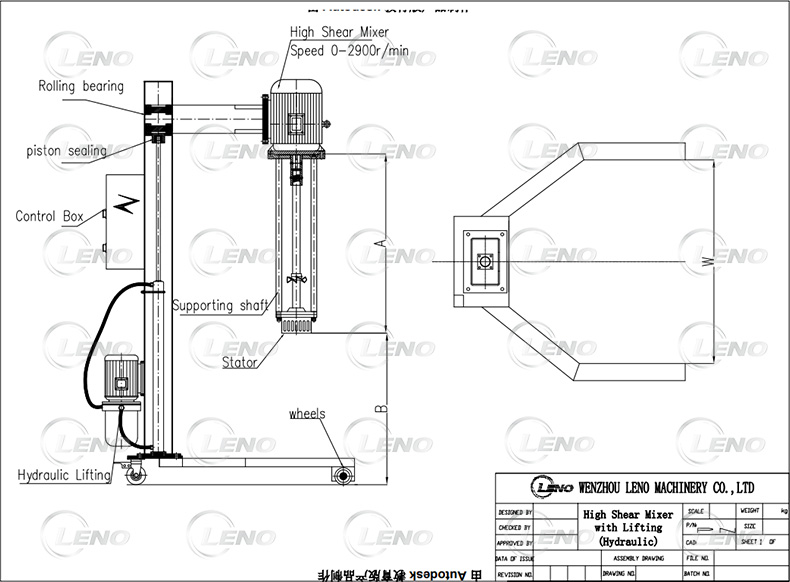

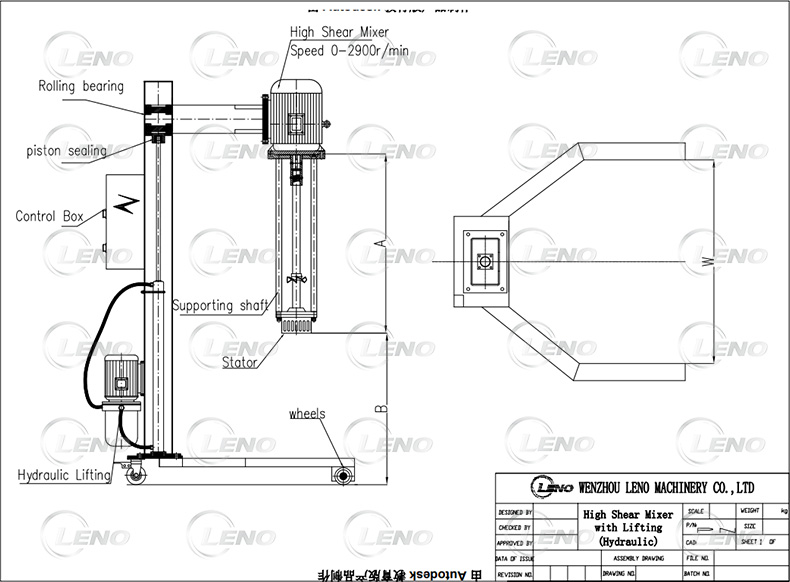

Integrated system concept built around key components: hydraulic oil pump, lifting height sensor, mixer, and control box.

Material flexibility to fit different corrosion/cleaning conditions: SS304 or SS316L, plus additional options such as coatings and 2205.

Engineering selection support to help match the mixer configuration to your vessel and your liquid behavior.

One-year quality assurance to reduce procurement risk and support stable commissioning.

This mixer fits B2B operations where uniformity is a customer requirement, not a nice-to-have. It is commonly selected when product performance is judged by texture, gloss, stability, or microscopic appearance.

Typical products and processes:

Personal care and cosmetics: lotions, creams, gels, serums, shampoos, conditioners, emulsified concentrates

Household and industrial chemicals: detergents, cleaners, dispersions, additive concentrates

Food and condiments: emulsified sauces, mayonnaise-style products, stable blends where mouthfeel and separation resistance matter

Powder wet-out steps where clumping causes rework, filtration load, or filling instability

What this means for buyers:

Fewer QC holds and fewer “mystery defects” that appear after cooling or storage

Smoother filling and packaging because the product behaves consistently

More predictable production planning because batches reach spec in a stable time window

High shear performance comes from a controlled rotor–stator zone where the product is repeatedly processed through a narrow gap.

What it improves in real production:

Emulsification quality: finer droplet size and better stability for oil–water systems

Dispersion and wet-out: fewer micro-lumps, less graininess, better additive distribution

Batch repeatability: less dependence on “mixing time guesses” and more reliance on defined parameters

Reduced rework: fewer extra mixing cycles and fewer corrective additions

Recommended validation methods:

Visual inspection under strong lighting, texture checks, viscosity trend tracking, stability tests, and downstream fill performance. Once validated, lock each SKU’s operating window into a standard procedure.

Large-vessel processing introduces challenges that small lab mixers never reveal: head positioning, operator safety, and repeatability across shifts.

Operational advantages:

Supports 100–1000 L tanks/drums with controlled vertical movement

Helps standardize head placement to reduce air entrainment and dead zones

Improves changeover discipline: lift, drain/clean, reposition, restart—faster and cleaner runs

Lifting height sensing supports more consistent operation and easier training

If your plant runs multiple products, hydraulic lifting becomes a productivity tool: it reduces the time spent “making it work” and increases the time spent producing consistent output.

Material choice is not just a spec; it’s a risk-control decision that affects corrosion resistance, cleaning compatibility, and long-term reliability.

Options and guidance:

SS304: common choice for many general industrial and hygienic applications

SS316L: preferred when corrosion resistance is more critical or cleaning chemistry is more aggressive

Coatings / 2205 availability: suitable for more demanding media where extra resistance is needed

Practical maintenance note:

High shear equipment is sensitive to buildup in the rotor–stator zone. A disciplined cleaning routine protects both performance and product hygiene. Cleanliness isn’t just sanitation—it prevents performance drift.

Because batch behavior depends on viscosity, vessel geometry, and formulation, equipment selection should be based on your real process—not generic assumptions.

Selection inputs that speed up a correct recommendation:

Batch volume range, viscosity range, and temperature conditions

Tank dimensions, opening constraints, and head access

Ingredient profile (powders, oils, thickeners, abrasives)

Cleaning method and chemical exposure

Quality targets (texture, stability, appearance) and expected cycle time

When selection is done correctly upfront, commissioning becomes smoother, operator training becomes faster, and batch-to-batch quality becomes easier to standardize.

| Parameter | Specification |

|---|---|

| Product name | Hydraulic lifting high shear mixer |

| Tank compatibility | 100 liter to 1000 liter tanks/drums |

| Mixing principle | Rotor–stator close-gap high shear; strong shear, turbulence, localized high velocity; supports thorough mixing and particle size reduction |

| System composition | Hydraulic oil pump, lifting height sensor, mixer, control box |

| Material options | SS304 or SS316L; coating options; 2205 available |

| Selection support | Engineering guidance to match drum/tank and size to different liquids |

| Quality assurance | One year |

A stable start requires a controlled commissioning plan, not a rushed first batch. High shear results are repeatable when positioning, cleaning, and inspection are standardized.

Recommended commissioning and operating plan:

Pre-install checklist: power readiness, safe lifting clearance, stable tank placement, defined cleaning workflow

Commissioning steps: water trial, then a controlled first batch with QC-aligned sampling checkpoints, then a repeat batch to confirm reproducibility

Cleaning discipline: focus on the rotor–stator area after every run to prevent residue hardening and performance drift

Long-term stability: schedule routine checks and keep a basic spare/consumable plan so maintenance is proactive, not reactive

For B2B plants, long-term value shows up as fewer unexpected stops, fewer quality disputes, and a shorter time-to-spec for each batch.

Focus on process outcomes: stable texture, consistent appearance, reduced rework—not just “it mixes.”

Hydraulic lifting supports repeatable placement, which is essential for large tanks and multi-shift operations.

Clear system composition supports standardized operation and easier troubleshooting.

Material options help match equipment to your corrosion risk and cleaning chemistry.

Engineering selection support reduces mismatch risk and speeds up commissioning.

One-year quality assurance supports procurement confidence.

Q1: What batch size is this mixer designed for?

It is positioned for large-vessel processing and is intended for 100–1000 liter tanks and drums. Your best configuration depends on viscosity, tank geometry, and quality targets.

Q2: How is high shear different from a normal agitator?

A normal agitator mainly moves bulk fluid. A rotor–stator high shear mixer forces product through a narrow gap to generate intense shear and turbulence, improving dispersion, wet-out, and emulsion stability.

Q3: What does the hydraulic lifting system include?

It is presented as a system with a hydraulic oil pump, lifting height sensor, mixer, and control box, supporting controlled positioning and repeatable operation.

Q4: Should I choose SS304 or SS316L?

SS304 is widely used for general applications. SS316L is better when corrosion resistance is more critical or cleaning chemicals are more aggressive. If your media is demanding, discuss coatings or 2205 availability.

Q5: How do you help select the right mixer for my liquid?

Selection is based on your batch volume, viscosity range, tank dimensions, temperature conditions, ingredient profile, and your QC targets for texture and stability.

Q6: What assurance is provided?

The product offers one-year quality assurance. For project success, align commissioning acceptance checks with your QC standards (uniformity, dispersion quality, repeatability).

In many factories, the word “mixing” hides the true cost: the hours spent fixing what didn’t disperse correctly. A shampoo can look perfect in the tank but reveal tiny specks under inspection lights. A cream can feel smooth at first touch, then show graininess after a day. A sauce can pass viscosity today and separate during transport tomorrow. These issues are rarely solved by “mix longer.” They’re solved by applying the right shear, in the right place, at the right time.

This hydraulic lifting high shear mixer is built for that critical moment. A rotor spins at high speed near a fixed stator, and the product is pulled through a narrow gap. In that tight zone, the material experiences strong shear, intense turbulence, and localized high velocity—conditions that help break down agglomerates, improve wet-out, and create finer, more stable emulsions. You can often sense the change during production: the surface becomes more uniform, the batch “pull” feels steadier, and the product’s appearance becomes cleaner as dispersion finishes sooner.

Because it’s designed for large vessels (100–1000 L), the hydraulic lifting structure matters as much as the shear head. Positioning a high shear head too shallow can draw air; too deep can reduce circulation efficiency. Hydraulic lifting helps turn “operator intuition” into a repeatable procedure—position, run, lift, clean—so quality is less dependent on who is on shift and more dependent on controlled process steps.

Rotor–stator high shear head for faster emulsification and dispersion, especially where ordinary agitators only move bulk fluid.

Hydraulic lifting system for controlled vertical positioning on large tanks and drums, improving repeatability and safety.

Integrated system concept built around key components: hydraulic oil pump, lifting height sensor, mixer, and control box.

Material flexibility to fit different corrosion/cleaning conditions: SS304 or SS316L, plus additional options such as coatings and 2205.

Engineering selection support to help match the mixer configuration to your vessel and your liquid behavior.

One-year quality assurance to reduce procurement risk and support stable commissioning.

This mixer fits B2B operations where uniformity is a customer requirement, not a nice-to-have. It is commonly selected when product performance is judged by texture, gloss, stability, or microscopic appearance.

Typical products and processes:

Personal care and cosmetics: lotions, creams, gels, serums, shampoos, conditioners, emulsified concentrates

Household and industrial chemicals: detergents, cleaners, dispersions, additive concentrates

Food and condiments: emulsified sauces, mayonnaise-style products, stable blends where mouthfeel and separation resistance matter

Powder wet-out steps where clumping causes rework, filtration load, or filling instability

What this means for buyers:

Fewer QC holds and fewer “mystery defects” that appear after cooling or storage

Smoother filling and packaging because the product behaves consistently

More predictable production planning because batches reach spec in a stable time window

High shear performance comes from a controlled rotor–stator zone where the product is repeatedly processed through a narrow gap.

What it improves in real production:

Emulsification quality: finer droplet size and better stability for oil–water systems

Dispersion and wet-out: fewer micro-lumps, less graininess, better additive distribution

Batch repeatability: less dependence on “mixing time guesses” and more reliance on defined parameters

Reduced rework: fewer extra mixing cycles and fewer corrective additions

Recommended validation methods:

Visual inspection under strong lighting, texture checks, viscosity trend tracking, stability tests, and downstream fill performance. Once validated, lock each SKU’s operating window into a standard procedure.

Large-vessel processing introduces challenges that small lab mixers never reveal: head positioning, operator safety, and repeatability across shifts.

Operational advantages:

Supports 100–1000 L tanks/drums with controlled vertical movement

Helps standardize head placement to reduce air entrainment and dead zones

Improves changeover discipline: lift, drain/clean, reposition, restart—faster and cleaner runs

Lifting height sensing supports more consistent operation and easier training

If your plant runs multiple products, hydraulic lifting becomes a productivity tool: it reduces the time spent “making it work” and increases the time spent producing consistent output.

Material choice is not just a spec; it’s a risk-control decision that affects corrosion resistance, cleaning compatibility, and long-term reliability.

Options and guidance:

SS304: common choice for many general industrial and hygienic applications

SS316L: preferred when corrosion resistance is more critical or cleaning chemistry is more aggressive

Coatings / 2205 availability: suitable for more demanding media where extra resistance is needed

Practical maintenance note:

High shear equipment is sensitive to buildup in the rotor–stator zone. A disciplined cleaning routine protects both performance and product hygiene. Cleanliness isn’t just sanitation—it prevents performance drift.

Because batch behavior depends on viscosity, vessel geometry, and formulation, equipment selection should be based on your real process—not generic assumptions.

Selection inputs that speed up a correct recommendation:

Batch volume range, viscosity range, and temperature conditions

Tank dimensions, opening constraints, and head access

Ingredient profile (powders, oils, thickeners, abrasives)

Cleaning method and chemical exposure

Quality targets (texture, stability, appearance) and expected cycle time

When selection is done correctly upfront, commissioning becomes smoother, operator training becomes faster, and batch-to-batch quality becomes easier to standardize.

| Parameter | Specification |

|---|---|

| Product name | Hydraulic lifting high shear mixer |

| Tank compatibility | 100 liter to 1000 liter tanks/drums |

| Mixing principle | Rotor–stator close-gap high shear; strong shear, turbulence, localized high velocity; supports thorough mixing and particle size reduction |

| System composition | Hydraulic oil pump, lifting height sensor, mixer, control box |

| Material options | SS304 or SS316L; coating options; 2205 available |

| Selection support | Engineering guidance to match drum/tank and size to different liquids |

| Quality assurance | One year |

A stable start requires a controlled commissioning plan, not a rushed first batch. High shear results are repeatable when positioning, cleaning, and inspection are standardized.

Recommended commissioning and operating plan:

Pre-install checklist: power readiness, safe lifting clearance, stable tank placement, defined cleaning workflow

Commissioning steps: water trial, then a controlled first batch with QC-aligned sampling checkpoints, then a repeat batch to confirm reproducibility

Cleaning discipline: focus on the rotor–stator area after every run to prevent residue hardening and performance drift

Long-term stability: schedule routine checks and keep a basic spare/consumable plan so maintenance is proactive, not reactive

For B2B plants, long-term value shows up as fewer unexpected stops, fewer quality disputes, and a shorter time-to-spec for each batch.

Focus on process outcomes: stable texture, consistent appearance, reduced rework—not just “it mixes.”

Hydraulic lifting supports repeatable placement, which is essential for large tanks and multi-shift operations.

Clear system composition supports standardized operation and easier troubleshooting.

Material options help match equipment to your corrosion risk and cleaning chemistry.

Engineering selection support reduces mismatch risk and speeds up commissioning.

One-year quality assurance supports procurement confidence.

Q1: What batch size is this mixer designed for?

It is positioned for large-vessel processing and is intended for 100–1000 liter tanks and drums. Your best configuration depends on viscosity, tank geometry, and quality targets.

Q2: How is high shear different from a normal agitator?

A normal agitator mainly moves bulk fluid. A rotor–stator high shear mixer forces product through a narrow gap to generate intense shear and turbulence, improving dispersion, wet-out, and emulsion stability.

Q3: What does the hydraulic lifting system include?

It is presented as a system with a hydraulic oil pump, lifting height sensor, mixer, and control box, supporting controlled positioning and repeatable operation.

Q4: Should I choose SS304 or SS316L?

SS304 is widely used for general applications. SS316L is better when corrosion resistance is more critical or cleaning chemicals are more aggressive. If your media is demanding, discuss coatings or 2205 availability.

Q5: How do you help select the right mixer for my liquid?

Selection is based on your batch volume, viscosity range, tank dimensions, temperature conditions, ingredient profile, and your QC targets for texture and stability.

Q6: What assurance is provided?

The product offers one-year quality assurance. For project success, align commissioning acceptance checks with your QC standards (uniformity, dispersion quality, repeatability).