Language

| Availability: | |

|---|---|

| Quantity: | |

Rotary lobe pump is used in a variety of industries including, pulp and paper, chemical, food, beverage, pharmaceutical, and biotechnology. They are popular in these diverse industries because they offer superb sanitary qualities, high efficiency, reliability, corrosion resistance, and good clean-in-place and sterilize-in-place (CIP/SIP) characteristics.

Lobe pump Options:

Material:AISI 304 AISI316

Seal Material:EPDM and PTFE

Flow:0-150T/H

Max.pressure:8bar

Max. working temperature: 0-150 C

Adjustable speed 0-1000 rmp

Rotor Type:2-leaves, 3-leaves, 5-leaves

Mechanical seal: SIC/SiC/EPDM(Standard)

Motor power: 0-22KW

Sealing option: Sanitary single mechanical seal/Double mechanical seal with cooling

Voltage: Single phase110V, 3Phase 220V, 380V/440V/660V

Motor: Inverter motor ,ABB, 50hz/ 60hz

Availably connection: Clamp, Thread Butt weld, Flange

Availably standard: DIN, SMS, 3A,

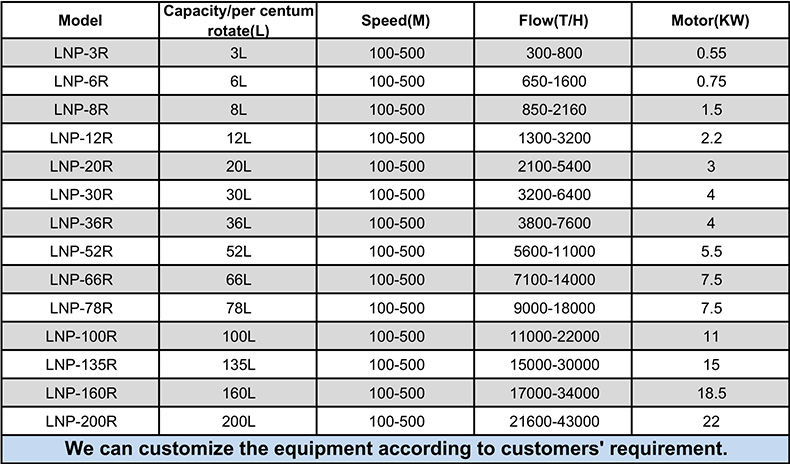

Lobe pump Parameter choose:

Chemical Industry: Used for transferring adhesives, sealants, paints, and coatings, including thick epoxy resins and silicone compounds.

Petroleum and Lubrication: Ideal for pumping heavy oils, greases, and lubricants in refineries and manufacturing plants.

Food Processing: Suitable for high-viscosity food products like peanut butter, molasses, and chocolate compounds, where consistent flow is essential.

Plastics and Polymers: Effective for handling molten plastics, polymer melts, and PVC compounds in extrusion and molding processes.

How Could we choose the right pump to match our production?

1:Production viscosity

2:Pump pressure

3:Liquid come with the soloid or not, if it had the solid ,we need know the size.

4:Pump Capacity

5:Application area.

Rotary lobe pump is used in a variety of industries including, pulp and paper, chemical, food, beverage, pharmaceutical, and biotechnology. They are popular in these diverse industries because they offer superb sanitary qualities, high efficiency, reliability, corrosion resistance, and good clean-in-place and sterilize-in-place (CIP/SIP) characteristics.

Lobe pump Options:

Material:AISI 304 AISI316

Seal Material:EPDM and PTFE

Flow:0-150T/H

Max.pressure:8bar

Max. working temperature: 0-150 C

Adjustable speed 0-1000 rmp

Rotor Type:2-leaves, 3-leaves, 5-leaves

Mechanical seal: SIC/SiC/EPDM(Standard)

Motor power: 0-22KW

Sealing option: Sanitary single mechanical seal/Double mechanical seal with cooling

Voltage: Single phase110V, 3Phase 220V, 380V/440V/660V

Motor: Inverter motor ,ABB, 50hz/ 60hz

Availably connection: Clamp, Thread Butt weld, Flange

Availably standard: DIN, SMS, 3A,

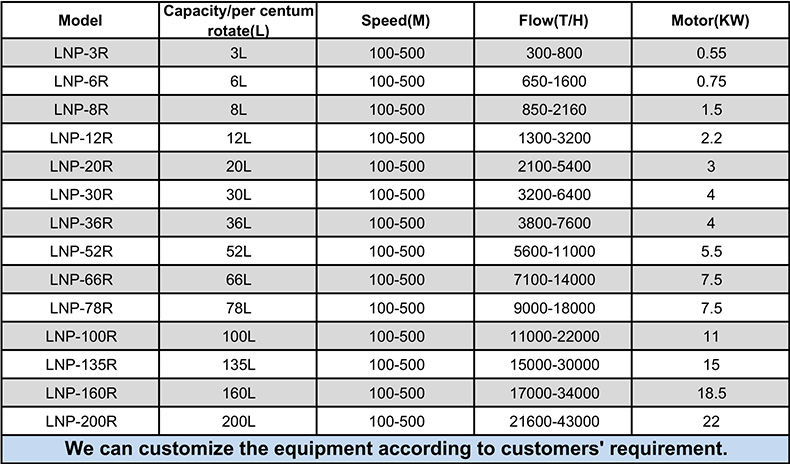

Lobe pump Parameter choose:

Chemical Industry: Used for transferring adhesives, sealants, paints, and coatings, including thick epoxy resins and silicone compounds.

Petroleum and Lubrication: Ideal for pumping heavy oils, greases, and lubricants in refineries and manufacturing plants.

Food Processing: Suitable for high-viscosity food products like peanut butter, molasses, and chocolate compounds, where consistent flow is essential.

Plastics and Polymers: Effective for handling molten plastics, polymer melts, and PVC compounds in extrusion and molding processes.

How Could we choose the right pump to match our production?

1:Production viscosity

2:Pump pressure

3:Liquid come with the soloid or not, if it had the solid ,we need know the size.

4:Pump Capacity

5:Application area.