Language

| Availability: | |

|---|---|

| Quantity: | |

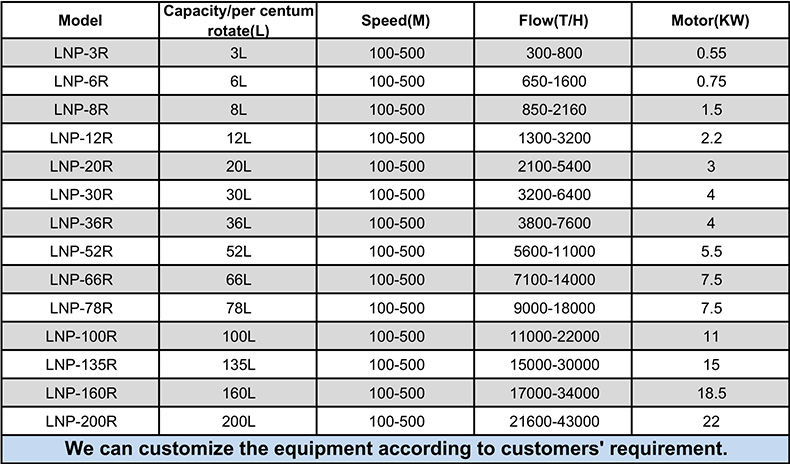

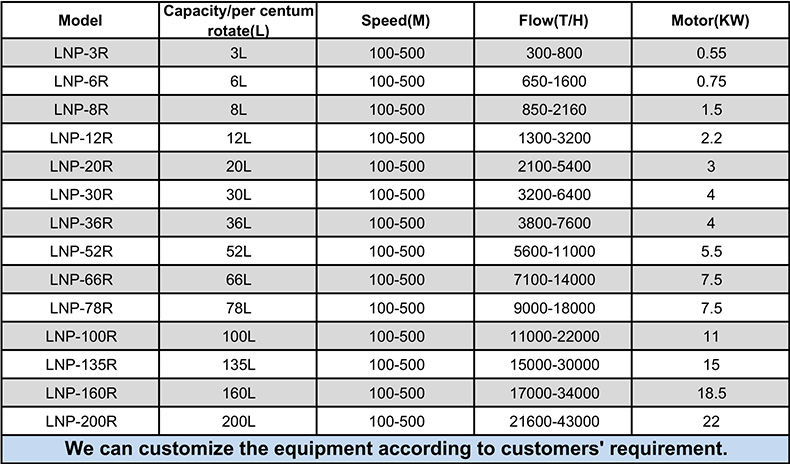

The High Viscosity Transferring Rotary Lobe Pump with Inverter is a specialized pumping solution engineered to handle extremely thick and viscous fluids with ease. Designed with robust lobed rotors and a heavy-duty casing, this pump excels in transferring materials that traditional pumps struggle with, such as greases, adhesives, polymers, and molten plastics. The integrated inverter allows for precise speed control, enabling operators to adjust flow rates dynamically to meet the demands of different processes. Built for durability and efficiency, this pump combines high-performance pumping with advanced control technology, making it a reliable choice for industrial applications requiring handling of high-viscosity media.

High Viscosity Handling: The large lobe geometry and wide inlet/outlet ports minimize resistance, allowing the pump to efficiently transfer fluids with viscosities up to 1,000,000 cP. This makes it suitable for materials that are nearly solid at room temperature.

Inverter Control: The built-in variable frequency drive (VFD) enables stepless speed adjustment from 0 to 1500 RPM, providing precise flow control and energy savings. The inverter also offers protection against overloads and voltage fluctuations.

Positive Displacement Design: The rotary lobe mechanism ensures a consistent flow rate regardless of pressure changes, making it ideal for metering applications where accuracy is critical.

Heavy-Duty Construction: The pump casing and rotors are made from high-strength alloys or stainless steel, with optional coatings for abrasion and corrosion resistance. This ensures long service life even in harsh industrial environments.

Low Pulsation Operation: The twin-lobe design creates a smooth flow with minimal pulsation, reducing stress on the pipeline and downstream equipment.

Chemical Industry: Used for transferring adhesives, sealants, paints, and coatings, including thick epoxy resins and silicone compounds.

Petroleum and Lubrication: Ideal for pumping heavy oils, greases, and lubricants in refineries and manufacturing plants.

Food Processing: Suitable for high-viscosity food products like peanut butter, molasses, and chocolate compounds, where consistent flow is essential.

Plastics and Polymers: Effective for handling molten plastics, polymer melts, and PVC compounds in extrusion and molding processes.

Q: How does the inverter benefit the pump's performance?

A: The inverter allows real-time speed adjustment, optimizing energy use and enabling precise flow control, which is crucial for processes requiring variable output.

Q: What is the maximum operating pressure?

A: The pump can handle pressures up to 10 bar, depending on the model and viscosity of the fluid.

Q: Can the rotors be replaced without disassembling the entire pump?

A: Yes, the pump features a split-case design that allows easy access to the rotors and seals for maintenance, reducing downtime.

Q: Is it suitable for shear-sensitive fluids?

A: While it's primarily designed for high viscosity, the gentle lobe action makes it suitable for moderately shear-sensitive materials; however, for extremely sensitive fluids, a sine pump may be a better choice.

The High Viscosity Transferring Rotary Lobe Pump with Inverter is a specialized pumping solution engineered to handle extremely thick and viscous fluids with ease. Designed with robust lobed rotors and a heavy-duty casing, this pump excels in transferring materials that traditional pumps struggle with, such as greases, adhesives, polymers, and molten plastics. The integrated inverter allows for precise speed control, enabling operators to adjust flow rates dynamically to meet the demands of different processes. Built for durability and efficiency, this pump combines high-performance pumping with advanced control technology, making it a reliable choice for industrial applications requiring handling of high-viscosity media.

High Viscosity Handling: The large lobe geometry and wide inlet/outlet ports minimize resistance, allowing the pump to efficiently transfer fluids with viscosities up to 1,000,000 cP. This makes it suitable for materials that are nearly solid at room temperature.

Inverter Control: The built-in variable frequency drive (VFD) enables stepless speed adjustment from 0 to 1500 RPM, providing precise flow control and energy savings. The inverter also offers protection against overloads and voltage fluctuations.

Positive Displacement Design: The rotary lobe mechanism ensures a consistent flow rate regardless of pressure changes, making it ideal for metering applications where accuracy is critical.

Heavy-Duty Construction: The pump casing and rotors are made from high-strength alloys or stainless steel, with optional coatings for abrasion and corrosion resistance. This ensures long service life even in harsh industrial environments.

Low Pulsation Operation: The twin-lobe design creates a smooth flow with minimal pulsation, reducing stress on the pipeline and downstream equipment.

Chemical Industry: Used for transferring adhesives, sealants, paints, and coatings, including thick epoxy resins and silicone compounds.

Petroleum and Lubrication: Ideal for pumping heavy oils, greases, and lubricants in refineries and manufacturing plants.

Food Processing: Suitable for high-viscosity food products like peanut butter, molasses, and chocolate compounds, where consistent flow is essential.

Plastics and Polymers: Effective for handling molten plastics, polymer melts, and PVC compounds in extrusion and molding processes.

Q: How does the inverter benefit the pump's performance?

A: The inverter allows real-time speed adjustment, optimizing energy use and enabling precise flow control, which is crucial for processes requiring variable output.

Q: What is the maximum operating pressure?

A: The pump can handle pressures up to 10 bar, depending on the model and viscosity of the fluid.

Q: Can the rotors be replaced without disassembling the entire pump?

A: Yes, the pump features a split-case design that allows easy access to the rotors and seals for maintenance, reducing downtime.

Q: Is it suitable for shear-sensitive fluids?

A: While it's primarily designed for high viscosity, the gentle lobe action makes it suitable for moderately shear-sensitive materials; however, for extremely sensitive fluids, a sine pump may be a better choice.