Language

| Availability: | |

|---|---|

| Quantity: | |

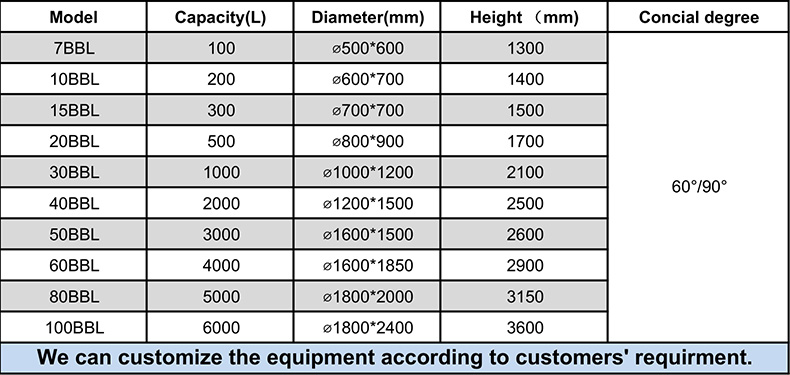

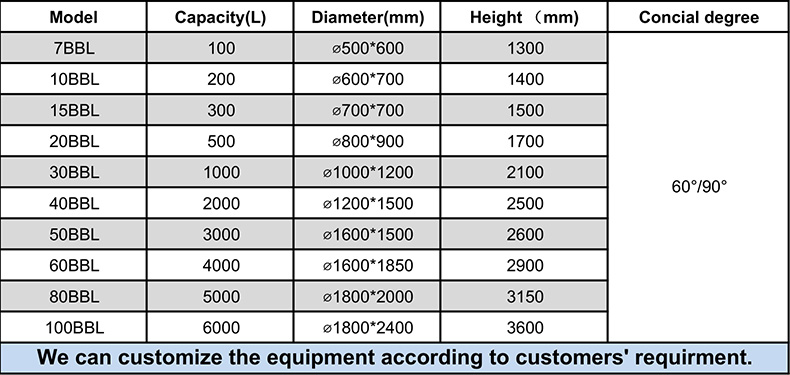

The Conical Beer Fermentation Tank is a cornerstone of modern brewing, designed to streamline the fermentation and conditioning of beer while optimizing yeast management and product quality. Its distinctive conical shape (typically 60-90° cone angle) enables efficient separation of trub (spent hops and yeast) and facilitates dry hopping, kräusen collection, or yeast harvesting for re-use. Constructed from 304 stainless steel with polished interiors, these tanks are engineered for durability, hygiene, and precise temperature control, making them essential for craft breweries, microbreweries, and large-scale production facilities.

Conical Geometry:

The tapered bottom concentrates sediment (trub and yeast) for easy removal, reducing the risk of off-flavors from prolonged contact. The design also supports closed-loop yeast propagation systems.

Thermal Efficiency:

Jacketed walls with dual-zone cooling (upper and lower sections) maintain fermentation temperatures between 5°C (lagers) and 25°C (ales). High-efficiency glycol chillers ensure rapid heat dissipation during active fermentation.

Pressure Fermentation Capability:

Rated for pressures up to 3 bar, the tank allows controlled carbonation during conditioning (forced carbonation) or pressure fermentation to suppress ester formation in clean-tasting lagers.

Hygienic Design:

Electropolished interiors (Ra ≤ 0.6μm), tri-clamp fittings, and CIP/SIP compatibility meet 3A Sanitary Standards. A tangential CO₂ vent prevents vortexing and oxygen pickup.

Modular Integration:

Equipped with digital pressure/temperature sensors, sample valves, and dry hop ports, the tank integrates seamlessly with brewery control systems for real-time process monitoring.

Lager Brewing: Maintains cold fermentation temperatures (7-12°C) for bottom-fermenting yeast strains, producing crisp, clean beers like Pilsners and Märzens.

Ale Production: Supports warmer temperatures (18-22°C) for top-fermenting yeast, ideal for IPAs, stouts, and sour beers requiring active yeast management.

Sour Beer and Wild Fermentation: Optional glycol jackets and airtight seals accommodate mixed culture fermentations ( Brettanomyces, Lactobacillus ) with precise temperature and oxygen control.

Nitrogenated Beers: Pressure-rated design enables direct infusion of nitrogen for creamy-textured stouts and nitro ales without external carbonation tanks.

Q: How does the cone angle affect yeast harvesting?

A: A steeper angle (90°) improves trub separation but requires more floor space; a shallower angle (60°) is space-efficient but may retain more sediment. Most breweries use 75° for balance.

Q: Can the tank be used for primary and secondary fermentation?

A: Yes—many breweries conduct both stages in the same tank to minimize handling, though dry hopping or flavor additions are typically done during secondary conditioning.

Q: What's the recommended headspace for fermentation?

A: Leave 20-30% headspace to accommodate krausen formation (foamy yeast layer), which can expand up to 1.5x the wort volume during peak fermentation.

Q: How is the tank sanitized between batches?

A: A typical CIP cycle includes pre-rinse, caustic wash (80°C, 30 minutes), acid rinse (phosphoric acid), and final sanitization with peracetic acid or iodophor solution.

The Conical Beer Fermentation Tank is a cornerstone of modern brewing, designed to streamline the fermentation and conditioning of beer while optimizing yeast management and product quality. Its distinctive conical shape (typically 60-90° cone angle) enables efficient separation of trub (spent hops and yeast) and facilitates dry hopping, kräusen collection, or yeast harvesting for re-use. Constructed from 304 stainless steel with polished interiors, these tanks are engineered for durability, hygiene, and precise temperature control, making them essential for craft breweries, microbreweries, and large-scale production facilities.

Conical Geometry:

The tapered bottom concentrates sediment (trub and yeast) for easy removal, reducing the risk of off-flavors from prolonged contact. The design also supports closed-loop yeast propagation systems.

Thermal Efficiency:

Jacketed walls with dual-zone cooling (upper and lower sections) maintain fermentation temperatures between 5°C (lagers) and 25°C (ales). High-efficiency glycol chillers ensure rapid heat dissipation during active fermentation.

Pressure Fermentation Capability:

Rated for pressures up to 3 bar, the tank allows controlled carbonation during conditioning (forced carbonation) or pressure fermentation to suppress ester formation in clean-tasting lagers.

Hygienic Design:

Electropolished interiors (Ra ≤ 0.6μm), tri-clamp fittings, and CIP/SIP compatibility meet 3A Sanitary Standards. A tangential CO₂ vent prevents vortexing and oxygen pickup.

Modular Integration:

Equipped with digital pressure/temperature sensors, sample valves, and dry hop ports, the tank integrates seamlessly with brewery control systems for real-time process monitoring.

Lager Brewing: Maintains cold fermentation temperatures (7-12°C) for bottom-fermenting yeast strains, producing crisp, clean beers like Pilsners and Märzens.

Ale Production: Supports warmer temperatures (18-22°C) for top-fermenting yeast, ideal for IPAs, stouts, and sour beers requiring active yeast management.

Sour Beer and Wild Fermentation: Optional glycol jackets and airtight seals accommodate mixed culture fermentations ( Brettanomyces, Lactobacillus ) with precise temperature and oxygen control.

Nitrogenated Beers: Pressure-rated design enables direct infusion of nitrogen for creamy-textured stouts and nitro ales without external carbonation tanks.

Q: How does the cone angle affect yeast harvesting?

A: A steeper angle (90°) improves trub separation but requires more floor space; a shallower angle (60°) is space-efficient but may retain more sediment. Most breweries use 75° for balance.

Q: Can the tank be used for primary and secondary fermentation?

A: Yes—many breweries conduct both stages in the same tank to minimize handling, though dry hopping or flavor additions are typically done during secondary conditioning.

Q: What's the recommended headspace for fermentation?

A: Leave 20-30% headspace to accommodate krausen formation (foamy yeast layer), which can expand up to 1.5x the wort volume during peak fermentation.

Q: How is the tank sanitized between batches?

A: A typical CIP cycle includes pre-rinse, caustic wash (80°C, 30 minutes), acid rinse (phosphoric acid), and final sanitization with peracetic acid or iodophor solution.